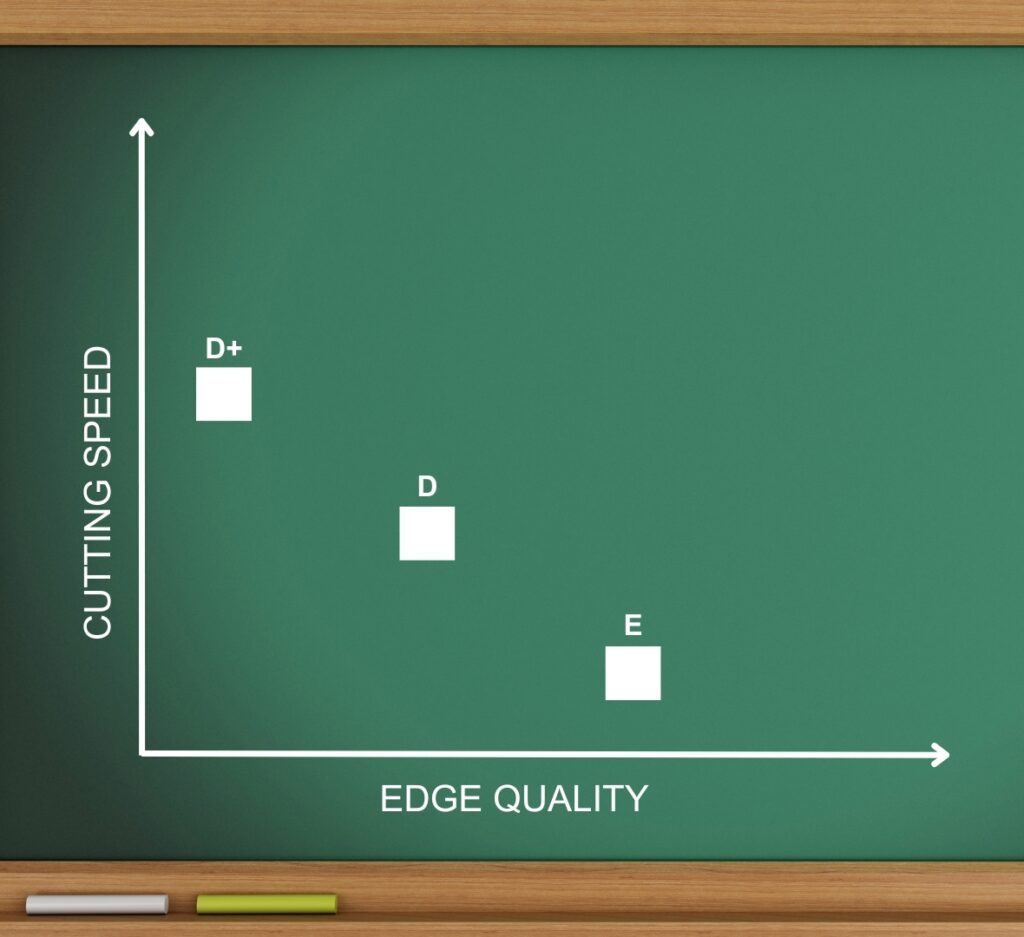

Suggested Grades

| Waterjet Cutting | Waterjet Cutting | D D+ E |

Garnet sand is a popular abrasive material used in waterjet cutting processes. Waterjet cutting is a modern and efficient cutting method that utilizes a high-pressure jet of water mixed with abrasive particles to cut through various materials, such as metal, stone, glass, ceramics, and composites.

Here’s how garnet sand is used in waterjet cutting :

Abrasive Material :

Garnet sand is one of the most commonly used abrasives in waterjet cutting due to its excellent properties. It is a natural mineral consisting mainly of almandine and pyrope, which are types of garnet. The grains of garnet are hard and sharp, making them ideal for cutting tough materials.

Mixing with Water :

In the waterjet cutting process, garnet sand is mixed with water to form an abrasive slurry. The mixture is then forced through a nozzle at extremely high pressure, typically ranging from 30,000 to 90,000 pounds per square inch (psi).

Cutting Process :

The high-pressure abrasive waterjet stream exits the nozzle at a very high velocity, which allows it to cut through the material being processed. The abrasive particles in the waterjet hit the surface of the workpiece, effectively eroding and cutting through the material.

Versatility :

Garnet sand is preferred in waterjet cutting because it is hard enough to cut through tough materials like metals, yet it is not excessively abrasive, which means it won’t cause excessive wear on the waterjet cutting equipment. It also produces a relatively smooth edge on the cut surface, reducing the need for additional finishing.

Environmental Considerations :

Garnet is a natural and non-toxic mineral, making it a safer and more environmentally friendly choice compared to some other abrasives used in cutting processes.

Recycling :

After the waterjet cutting process, the abrasive slurry containing garnet and the cut material can be separated using a filtration system. The garnet can be recycled and reused several times before it becomes too small or worn out for effective cutting, reducing waste and overall costs.

Overall, garnet sand is a reliable and efficient abrasive material for waterjet cutting applications, offering a balance between cutting performance, cost-effectiveness, and environmental impact.