Resin Coated Sand is widely applied in Foundry industries using various molding process. It is dried washed & sieved quartz sand, which manufactured with mixing the resin material (Phenol Formaldehyde & Furan) & hardener (Hexamine) at high temperature, where resin melts & covers every quartz grains, which helps to bind & stiffen the quartz sand to produce the solid, tough & strong molds. The percentage of resin & hardener are depending on the process of casting & metal type.

CAPPEX RCS: We, Cappex India are one of the leading manufacturers of Resin Coated Sand, since 1998, with having multiple quality grades as per the casting methods & metal type. We have differentiated grades as per various applications after having years of experience with our clients’ needs. Cappex India highly believes in customization. We can supply Custom Made RCS based on customer requirements

In Foundry Industry, Major Problems Occurs.

- Fusion of Sand

- Shake out Problem while De-coring

- Gas Evaluation Defects

- Surface Finishing

- Load Bearing Strength & much more

To overcome these problems, we use high quality Phenol Formaldehyde & Hardener, with filling high percentage in every lot of production, which helps to :

1. Proper & Hard Bonding Structure at time of sand fusion (Reduce finishing cost of metal).

2. Due to high strength, no shake-out problem occur during De-coring (Helps in perfect shaping).

3. Due to strong bond, low leakage of gas evaluation (Helps to maintain the work piece structure).

4. Because of no porosity, the sand has good flowability, which gives better surface finishing.

5. Because of high strength & bonding, the sand can bear more weight, which reduce the breakage of molds.

Our RCS Available Grades

Edit Content

CAPPEX RCS for Aluminum Casting, have differentiated in various grades as per the applications in various foundries. Our RCS gives excellent surface finish & maintain lower gas evaluation during pouring.

| GRADE | AFS | HITS KGS/CM² | CTS KGS/CM² | GAS CONTENT | LOI | APPLICATIONS |

|---|---|---|---|---|---|---|

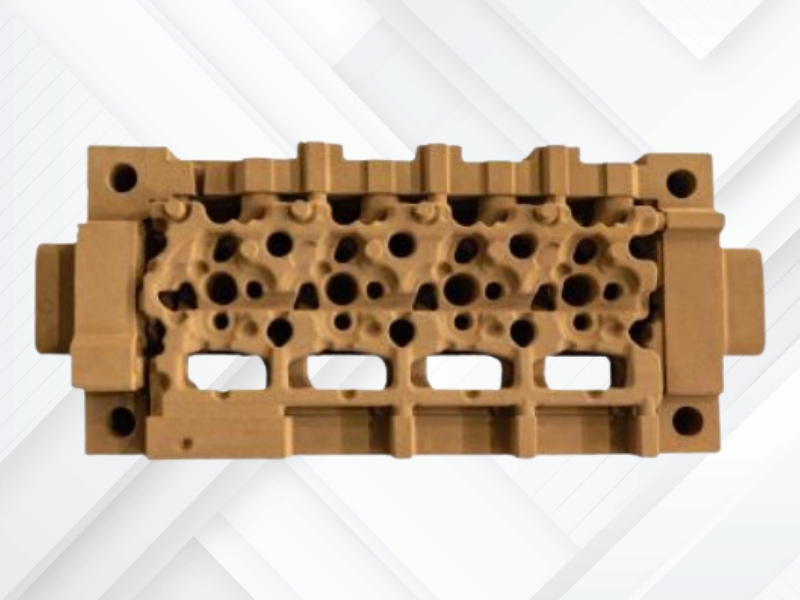

| RCS-AL-A | 50-55 | 10-12 | 20-22 | 5-6 C.C. | 1.6 | Water Jacket & Cylinder Head |

| RCS-AL-B | 60-65 | 12-14 | 24-26 | 7-8 C.C. | 1.8 | General Application |

| RCS-AL-C | 70-80 | 16-18 | 30-32 | 10-12 C.C. | 2.3 | Manifold & Hollow Casting |

| RCS-AL-D | 95-100 | 18-20 | 36-38 | 14-16 C.C. | 2.6 | Special Applications |

Applications :

Edit Content

Ferrous particularly includes Steel, Cast Iron, and Alloy Cast Iron, where we have differentiated two categories for various molding.

| GRADES | MOLDING TYPE | AFS | HTS KGS/CM² | CTS KGS/CM² | LOI | GAS CONTENT | APPLICATIONS |

|---|---|---|---|---|---|---|---|

| RCS-F-SM | ForSeriesofMoldings | All | 26-30 | 39-43 | 3.5%MAX | 15-17 C.C. | Turbine Hosing, Cran & Cam Shaft, Rocker Arm, Valve Guide, Gear Boxes & much more. |

| RCS-F-DB | For Molding By Dump Box | All | 33-37 | 49-53 | 4.5%MAX | 17-21 C.C. | #rowspan# |

Applications :

Advantages :

- Better HTS & High CTS.

- No Crack, while joining.

- No porosity.

- Low Gas Defeats.

- No cores Breakages.

- Low Sand Consumption.

- Excellent Surface Finishing.

- High Strength.

- Equable Wall Thickness.

- Sustain High Core Weight & Volume.

Edit Content

| GRADES | MOLDINGTYPE | AFS | HTSKGS/CM² | CTSKGS/CM² | LOI | GASCONTENT | Applications |

|---|---|---|---|---|---|---|---|

| RCS-F-S-SM | All | ForSeriesofMoldings | 21-24 | 31-35 | 3.5%MAX | 11-13C.C. | ToothPoints,Anchors,ValveBodies,SideCutters&muchmore. |

| RCS-F-S-DB | All | ForMoldingByDumpBox | 33-37 | 51-55 | 4.5%MAX | 17-21C.C. | #rowspan# |

Applications :

Advantages :

- Specialized Grade.

- Smooth ejection of Molds.

- No sub surface cracks.

- No mold crack when pouring.

- Give CTS almost 70% higher than HTS.

- Improve collapsibility.

- No Peel back.

- Better Compactness.

Edit Content

Non-ferrous particular includes copper based alloy, brass, & bronze. Majorly for non-ferrous alloys & metals, we produce variety of grades with 3-5% resin & are available for 40-45 to 95-100 AFS. We only produce RCS on customer needs in this category.